-

Copper Foil Shielding

-

RF Shielded Doors

-

RF Shielded Windows

-

Radiation Protection Lead Glass

-

Non Magnetic Tool Kit

-

Nuclear Radiation Protection

-

Nuclear Radiation Detector

-

RF Shielded Chamber

-

Honeycomb Waveguide Air Vents

-

Conductive Adhesive Copper Tape

-

Copper Wire Mesh

-

X Ray Lead Glass

-

EMI Shielding Gasket

-

Electrically Conductive Fabric

-

Radiation Protection Door

-

Radiation Protection X Ray

-

Faraday Cage MRI

-

Copper Wire Wool

-

MRI LED Lighting

-

Non Magnetic Wheelchair

-

Non Magnetic Stretcher

-

AnasBrass honeycomb vent Looks Very Nice

AnasBrass honeycomb vent Looks Very Nice -

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

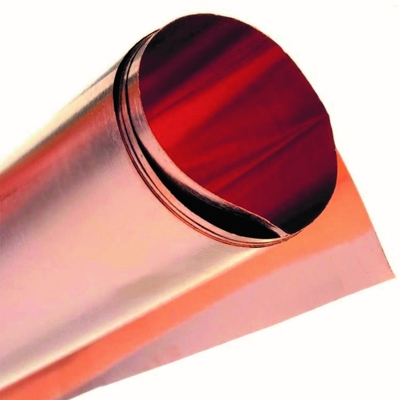

0.15mm Wrought Copper Foil Sheet High Precision Rolled 600mm

| Product Name | 0.15mm High-Precision Rolled-Wrought Copper Foil Sheet 600mm | Material | Pure Copper |

|---|---|---|---|

| Usage | Faraday Cage, MRI Room Installation | Thickness | 0.1mm |

| Application | Rf Door, Rf Window, MRI Room Install | Tensile Strength | Excellent |

| Width | 0.6 -- 1.5m Special Can Be Customized | ||

| Highlight | wrought copper foil sheet,0.15mm copper foil sheet |

||

0.15mm High-Precision Rolled-Wrought Copper Foil Sheet 600mm

Description:

High-precision rolled copper foil is a high-quality material,compared to ordinary copper foil products, it has higher purity, better surface finish, better flatness, more precise tolerances and more perfect processing properties. The high precision copper foil has been also degrease

and anti-oxidized, which allows the foil to have longer shelf life and be easier to laminate with other materials.

As the material is manufactured and packaged in dust free room, the cleanliness of the product is very high and it meets the requirements of a high-end electronics production environment.

Copper foil is an indispensable raw material for making printed circuit board (PCB), copper clad laminate (CCL) and lithium-ion battery.

Industrial copper foil can be divided into calendered copper foil and electrolytic copper foil according to its manufacturing process.

Electrolytic copper foil is made by copper electrolysis based on electrochemical principle.

The internal structure of the green foil is vertical needle crystal structure, and its production cost is relatively low.

Calendered copper foil is formed by repeated rolling annealing process of copper ingot based on the principle of plastic processing. Its internal structure is flake crystalline structure, and the ductility of calendered copper foil products is good.

At present, electrolytic copper foil is mainly used in the production of rigid circuit boards,

while calendered copper foil is mainly used in flexible and high-frequency circuit boards.

RA copper foil

| Thickness | 0.1mm /0.15mm | 0.15mm-0.5mm |

| Width | 150mm/300mm/600mm | 600mm/800mm |

ED copper foil

| Quality Items | General Technical Terms | ||||

| Normal thickness | 2oz | 3oz | 4oz | 5oz | |

| 0.07mm | 0.105mm | 0.14mm | 0.175mm | ||

| Area Weight(g/m2) | 560-610 | 838-960 | 1100-1280 | 1380-1600 | |

| Tensile strength | Room temperature | ≥28 | ≥28 | ≥28 | ≥28 |

| (kg/mm2) | |||||

| Elongation | Room temperature | ≥10 | ≥10 | ≥10 | ≥10 |

| % | |||||

| Leakage points(points/m2) | No | ||||

| High-temperature Anti-Oxidization Performance(180℃/h) | No Oxidization | ||||

| Width Tolerance | (+2.0 ,-2.0) | ||||

Production line

![]()

Application Of copper foil

As we can see in the picture, copper foil can be widely used in MRI RF shielding room installation.

Such as ceiling, wall, and floor. It can effectively prevent the leakage of signals and noise.![]()

Q1. How do I pay for my purchase order?

A: We can accept the following payment methods: T/T, L/C, D/A, D/P, and we also can accept Westernunion

If you want another payment please contact us.

Q2. Is there a tracking number for my item?

A: Yes, of course. We usually ship your goods by EMS, DHL, FedEx, UPS, TNT with the online track,

you can view the shipment status on the website.

Q3. How does your factory do related quality control?

A: Quality is a top priority. We attach great importance to quality control from the very beginning of manufacturing.