-

Copper Foil Shielding

-

RF Shielded Doors

-

RF Shielded Windows

-

Radiation Protection Lead Glass

-

Non Magnetic Tool Kit

-

Nuclear Radiation Protection

-

Nuclear Radiation Detector

-

RF Shielded Chamber

-

Honeycomb Waveguide Air Vents

-

Conductive Adhesive Copper Tape

-

Copper Wire Mesh

-

X Ray Lead Glass

-

EMI Shielding Gasket

-

Electrically Conductive Fabric

-

Radiation Protection Door

-

Radiation Protection X Ray

-

Faraday Cage MRI

-

Copper Wire Wool

-

MRI LED Lighting

-

Non Magnetic Wheelchair

-

Non Magnetic Stretcher

-

AnasBrass honeycomb vent Looks Very Nice

AnasBrass honeycomb vent Looks Very Nice -

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

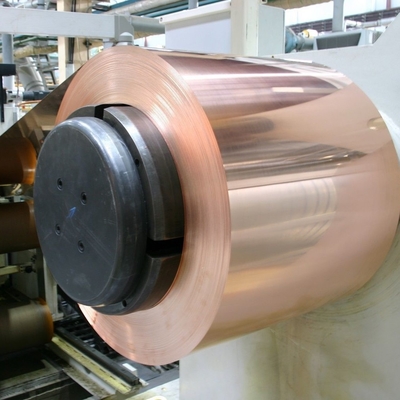

8 Micron Electrodeposited Copper Foil Shielding For Rf Cage Mri Room

| Product Name | Electrodeposited Copper Foil Shielding For Rf Cage Mri Room | Material | Pure Copper |

|---|---|---|---|

| Thickness | 8 Micron Meter To 0.5mm | Width | 650mm1320mm |

| MOQ | 200kg | Packing | Wooden Case |

| Application | MRI RF Shielding Project, Faraday Cage | ||

| Highlight | mri room copper foil shielding,8 micron copper foil shielding,electrodeposited copper foil sheet |

||

Electrodeposited Copper Foil Shielding For Rf Cage Mri Room

Description:

Electrolytic copper foil is an important material for the manufacture of copper clad laminates (CCL) and printed circuit boards (PCBs)

and lithium ion batteries. In the rapid development of today's electronic information industry, electrolytic copper foil is called the "neural network" of electronic product signal and power transmission and communication. Since 2002, the production value of China's printed circuit boards has entered the third place in the world. As the substrate material for PCBs, CCL has also become the third largest producer in the world.

Electrolytic copper foil production process is simple, the main process has three: solution foil, surface treatment and product slitting. Its production process seems simple, but it is a combination of electronics, machinery and electrochemistry, and it is a production process that requires particularly strict production environment.

Specification:

| Quality Items | General Technical Terms | |||||

| Normal Thickness | 2oz | 3oz | 4oz | 5oz | 6oz | |

| 0.07mm | 0.105mm | 0.140mm | 0.175mm | 0.210mm | ||

| Area Weight(g/m2) | 560-610 | 838-960 | 1100-1280 | 1380-1600 | 1650-1920 | |

| Tensile Strength | Room Temperature | ≥28 | ≥28 | ≥28 | ≥28 | ≥28 |

| (kg/mm2) | ||||||

| Elongation | Room Temperature | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 |

| (%) | ||||||

| Leakage Points (points/m2) | No | |||||

| High Temperature Anti-Oxidization Performance(180℃/h) | No Oxidization | |||||

| Width Tolerance | (+2.0,-2.0) | |||||

![]()

FAQ:

A. What service can you offer?

a: High quality products, competitive price, warmly following until you receive, and also technical support during use once you need.

B. What is MOQ ?

b: 200kg per roll.

C. What is the delivery time?

c. 5-8 working days after receiving payment.

D. What shipment way can you offer?

d. By air, by sea, by train.