-

Copper Foil Shielding

-

RF Shielded Doors

-

RF Shielded Windows

-

Radiation Protection Lead Glass

-

Non Magnetic Tool Kit

-

Nuclear Radiation Protection

-

Nuclear Radiation Detector

-

RF Shielded Chamber

-

Honeycomb Waveguide Air Vents

-

Conductive Adhesive Copper Tape

-

Copper Wire Mesh

-

X Ray Lead Glass

-

EMI Shielding Gasket

-

Electrically Conductive Fabric

-

Radiation Protection Door

-

Radiation Protection X Ray

-

Faraday Cage MRI

-

Copper Wire Wool

-

MRI LED Lighting

-

Non Magnetic Wheelchair

-

Non Magnetic Stretcher

-

AnasBrass honeycomb vent Looks Very Nice

AnasBrass honeycomb vent Looks Very Nice -

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

Width 1320mm Copper Foil Shielding Electrodeposited Sheet Sgs

| Material | 1320mm Width Electrodeposited Copper Foil Sheet Shielding SGS | ED Copper Foil | 1295mm 1285mm 1320mm 1370mm |

|---|---|---|---|

| ED Copper Foil Thickness | 0.07mm 0.105mm 0.14mm | Shielded Frequency | >100db In Band 10MHz-130MHz |

| Purity | 99.85% | Delivery Time | 5-8working Days |

| Color | Copper | Thickness | 20-150micron,19-150u |

| Usage | MRI Room,Shielding EMI,electromagnetic Shielding,Conductive Shielding | Product Name | Copper Foil Tape |

| Highlight | width 1320mm copper foil shielding,sgs copper foil shielding,shielding electrodeposited copper foil |

||

1320mm Width Electrodeposited Copper Foil Sheet Shielding SGS

APPLICATION & SPECIFICATION

Electrodeposited copper foil TRZA-HTE (IPC-4562/3 Cu-E3) is high quality electrodeposited copper foil with zinc coating and low profile, which has higher elongation at high temperatures as per IPC-4562 requirements. Zinc coating allows it to be used for the fabrication of rigid CCL & MLB with higher lamination temperature (high Tg FR-4, FR-5, PTFE).

Specification of ED copper foil

| Qualtiy Items | General Technical Terms | ||||

| Normal thickness | 2oz | 3oz | 4oz | 5oz | |

| 0.07mm | 0.105mm | 0.14mm | 0.175mm | ||

| Area Weight(g/m2) | 560-610 | 838-960 | 1100-1280 | 1380-1600 | |

| Tensile strength | Room temperature | ≥28 | ≥28 | ≥28 | ≥28 |

| (kg/mm2) | |||||

| Elongation | Room temperature | ≥10 | ≥10 | ≥10 | ≥10 |

| % | |||||

| Leakage points(points/m2) | No | ||||

| High temperature Anti-Oxidization Performance(180℃/h) | No Oxidization | ||||

| Width Tolerance | (+2.0 ,-2.0) | ||||

| Item | Unit | Condition | Specification value | Inspection frequencies | Test method | ||||

| 12 um | 18 um | 35 um | 70 um | 105 um | |||||

| Purity | % | A | ≧ 99.8 | C | IPC-TM-650-2.3.15 | ||||

| Area weight | g/㎡ | A | 107±10 | 152±15 | 305±30 | 610±61 | 915±91 | А | IPC-TM-650-2.2.12 |

| Untreated Side Roughness (Ra) | um | A | <0.43 | А | IPC-TM-650-2.2.17 | ||||

| Treated Side Roughness(Rz) | um | A | ≤7 | ≤8 | ≤10 | ≤14 | ≤14 | А | IPC-TM-650-2.2.17 |

| Tensile strength | kg/mm2 | A | ≥21 | ≥21 | ≥28 | ≥28 | ≥28 | А | IPC-TM-650-2.4.18 |

| 180℃ | ≥15 | ≥15 | ≥15 | ≥15 | ≥15 | А | |||

| Elongation | % | A | ≥3 | ≥4 | ≥5 | ≥5 | ≥5 | А | IPC-TM-650-2.4.18 |

| 180℃ | ≥3 | ≥3 | ≥3 | ≥3 | ≥3 | А | |||

| Peel strength (RT) FR-4 | kg/cm | A | ≥1.0 | ≥1.3 | ≥1.7 | ≥2.1 | ≥2.3 | А | IPC-TM-650-2.4.8 |

| Item | Unit | Condition | Specification value | Inspection frequencies | Test method | |||

| 8 um | 10 um | 12 um | 18 um | |||||

| Purity | % | A | ≥ 99.9 | C | IPC-TM-650-2.3.15 | |||

| Area weight | g/㎡ | A | 72±4 | 89±5 | 107±5 | 155±8 | А | IPC-TM-650-2.2.12 |

| Drum Side Roughness (Ra) | um | A | ≤ 0.4 | А | IPC-TM-650-2.2.17 | |||

| Electrolyte Side Roughness(Rz) | um | A | ≤ 3.5 | А | IPC-TM-650-2.2.17 | |||

| Tensile strength | kg/mm2 | A | ≥ 35 | А | IPC-TM-650-2.4.18 | |||

| Elongation | % | A | ≥ 3 | ≥ 4 | А |

IPC-TM-650-2.4.18 |

||

![]()

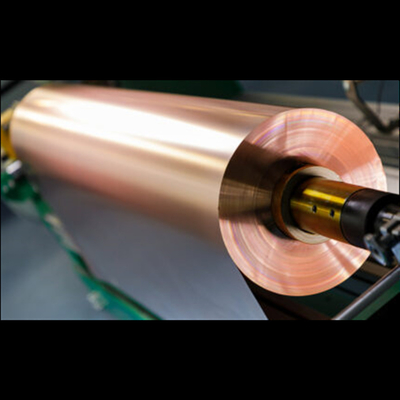

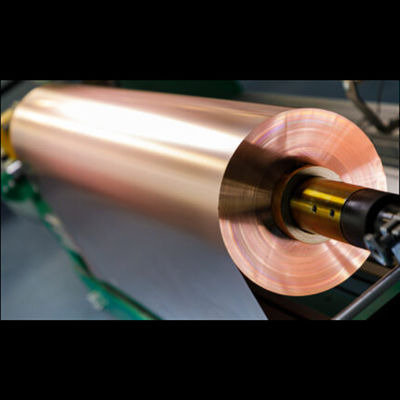

Production line

Full production line of copper foil

| step 1 | High purity copper wire |

| step 2 | Soluble copper |

| step 3 | Crude ED copper foil |

| step 4 | Cutting |

| step 5 | Finished products |

| step 6 | Inspection |

| step 7 | Packing |

![]()

Application Of copper foil

Copper is great material of shielded signal .Widely used for rf cage /MRI room installations,building roof to protect out of oxidizition .

There are two main installation ways of RF cage building .

First option :

ED copper foil 1320mm -basic step- Make Wooden Panel +Put copper foil Covered wooden frame

+assemle copper foil wooden panel together.

Finished RF shielded cage as below:

![]()

Second option :

RA copper foil 600mm- basic step -Make bending edges of copper sheet

+Fix sheets on wood walls +welding edges of 2 pcs sheets together.

Finished RF shielded cage as below:

![]()

F&A

Q1. Can I have a sample order for Ed Copper foil ?

A: Yes, we welcome sample order to test and check quality. Free A4 ED copper foil sample .

Q2. How do you ship the goods and how long does it take to arrive?

A: Ship by DHL, UPS, FedEx or TNT. Airline and sea shipping also optional.

Q3. Do you have any MOQ limit ?

A: Low MOQ, 200kg for ED copper foil 1320mm ,500kg for RA copper foil 600mm