-

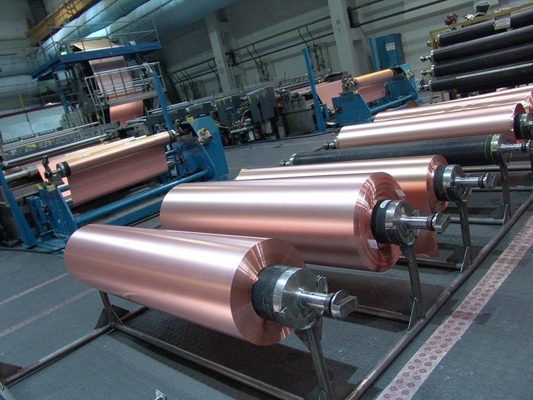

Copper Foil Shielding

-

RF Shielded Doors

-

RF Shielded Windows

-

Radiation Protection Lead Glass

-

Non Magnetic Tool Kit

-

Nuclear Radiation Protection

-

Nuclear Radiation Detector

-

RF Shielded Chamber

-

Honeycomb Waveguide Air Vents

-

Conductive Adhesive Copper Tape

-

Copper Wire Mesh

-

X Ray Lead Glass

-

EMI Shielding Gasket

-

Electrically Conductive Fabric

-

Radiation Protection Door

-

Radiation Protection X Ray

-

Faraday Cage MRI

-

Copper Wire Wool

-

MRI LED Lighting

-

Non Magnetic Wheelchair

-

Non Magnetic Stretcher

-

AnasBrass honeycomb vent Looks Very Nice

AnasBrass honeycomb vent Looks Very Nice -

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

adhesive copper tape copper sheet coil copper foils for shielding

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Mqq | 200kg | Alloy Or Not | Non-alloy |

|---|---|---|---|

| Width | 1320 | Application | MRI Room Construction |

| Highlight | adhesive non alloy copper foil shielding,1320mm width copper foil shielding,copper shielding tape with conductive adhesive |

||

Product Application

Ed shielding copper foil with high elongation and high tensile strength, can be used in many fields. We can offer specific lithium-ion battery, double matte and double shiny ED copper. We can also provide 2OZ to 6oz (nominal thickness 70um to 210um) shielded ED copper foil for electrical product shielding, in particular, transformers, cables, mobile phones, computers, mechanical processing, aerospace, and so on. More importantly, HTE (high temperature elongation) copper foil from 1/2 oz to 2 oz and VLP-HTE-HF (extremely low thickness, high temperature elongation, heavy ED copper foil, for PCB, with a maximum size of 1295 mm x 2450 mm.

ED Copper Foil Specification

| Quality Items | General Technical Terms | |||||

| 2oz (70um) |

3oz (105um) |

4oz (0.14mm) |

5oz (175um) |

6oz (210um) |

||

| Area Weight g/m2 | 585±25 | 915±45 | 1220±60 | 1525±75 | 1830±90 | |

| Tensile Strength kg/mm2 |

Room Temperature |

≥25.0 | ≥25.0 | ≥25.0 | ≥25.0 | ≥25.0 |

| Elongation % |

Room Temperature |

≥5.0 | ≥5.0 | ≥5.0 | ≥5.0 | ≥5.0 |

| Leakage Points points/m2 |

No | No | No | No | No | |

| Quality of electrical resistivity Ω·g /m2 |

≤0.162 | ≤0.162 | ≤0.162 | ≤0.162 | ≤0.162 | |

| Anti-Oxidization Performance 160 centigrade/30min |

No Oxidization | No Oxidization | No Oxidization | No Oxidization | No Oxidization | |

| Width Tolerance mm |

1290.0±1.0 | 1320.0±1.0 | 1320.0±1.0 | 1370.0±1.0 | 1370.0±1.0 |

| Quality Items | General Technical Terms | |||||

| 2oz(70um) | 3oz(105um) | 4oz(140um) | 5oz(175um) | 6oz(210um) | ||

| Area Weight g/m2 | 585±25 | 915±45 | 1220±60 | 1525±75 | 1830±90 | |

| Tensile Strength kg/mm2 | Room Temperature | ≥25.0 | ||||

| Elongation% | Room Temperature | ≥5.0 | ||||

| Leakage Point points/m2 | NO | |||||

| Quality of electrical resistivity Ωg/m2 | ≤0.162 | |||||

| Anti-Oxidization Performance 160 centigrade/30min | No Oxidization | |||||

| Width Tolerance mm | 1380.0±1.0 | |||||