-

Copper Foil Shielding

-

RF Shielded Doors

-

RF Shielded Windows

-

Radiation Protection Lead Glass

-

Non Magnetic Tool Kit

-

Nuclear Radiation Protection

-

Nuclear Radiation Detector

-

RF Shielded Chamber

-

Honeycomb Waveguide Air Vents

-

Conductive Adhesive Copper Tape

-

Copper Wire Mesh

-

X Ray Lead Glass

-

EMI Shielding Gasket

-

Electrically Conductive Fabric

-

Radiation Protection Door

-

Radiation Protection X Ray

-

Faraday Cage MRI

-

Copper Wire Wool

-

MRI LED Lighting

-

Non Magnetic Wheelchair

-

Non Magnetic Stretcher

-

AnasBrass honeycomb vent Looks Very Nice

AnasBrass honeycomb vent Looks Very Nice -

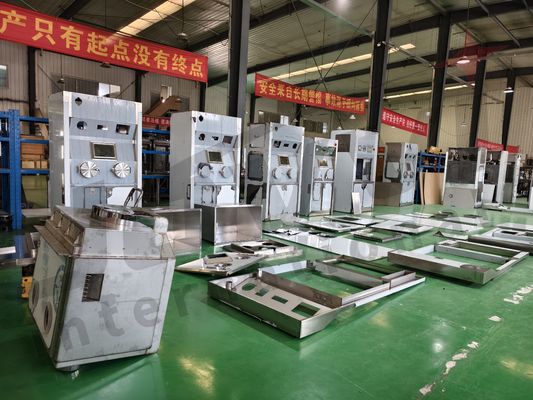

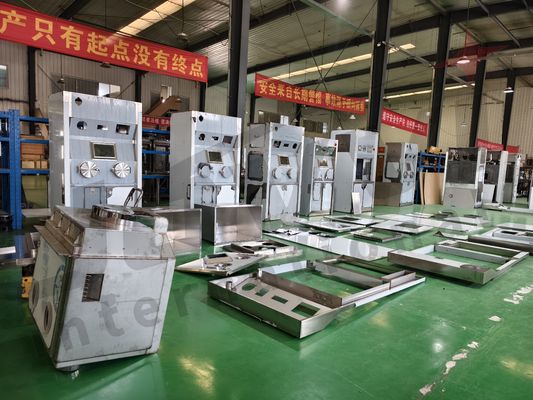

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

Hepa Filtration I131 Hot Cell Provide Nuclear Facilities With Secure And Purification Of Radioactive Isotopes

| Model | Jovvi-50mmpb | Design | Ergonomic Design For Ease Of Movement |

|---|---|---|---|

| Application | Nuclear Facilities | Purification Method | Active Carbon Filter,Hepa Filtration, |

| Disinfection Method | Ultraviolet Light And Ozone | Function | Shielding Gamma And X-ray Radiation |

| Type | Radiation Shielding Protective | Operation System | Artificial Intelligence Control |

| Highlight | Hepa Filtration Hot Cell,Nuclear Facilities Hot Cell,Ergonomic Hot Cell |

||

Product Description:

The JOVI-50mmpb Nuclear Radiation Protection System is an advanced shielding solution engineered to provide high‑performance attenuation of gamma and X‑ray radiation. Constructed from a durable composite of galvanized steel and lead sheeting, the system delivers reliable protection in environments where nuclear medical radiation is present, such as nuclear facilities and specialized medical settings like F‑18 hot cells. It serves as a robust barrier against radiation exposure, safeguarding personnel and sensitive equipment in critical applications.

The system’s primary function is to effectively shield against highly penetrating gamma and X‑ray radiation, which are commonly encountered in nuclear medicine, radiopharmaceutical production, and industrial radiography. The combination of galvanized steel and lead layers optimizes density and structural integrity, significantly reducing radiation transmission and helping facilities meet stringent safety standards.

Galvanized steel forms the structural framework, offering corrosion resistance and durability even in demanding environments. The embedded lead sheeting acts as the primary radiation attenuator, leveraging lead’s high density and atomic number to absorb ionizing radiation. This hybrid construction ensures both long‑term reliability and consistent shielding performance, making the system suitable for continuous use in controlled settings such as F‑18 hot cells.

F‑18 hot cells are shielded enclosures used for handling radioactive materials—particularly fluorine‑18 isotopes for positron emission tomography (PET)—requiring strict containment to protect operators. The JOVI‑50mmpb is designed to integrate seamlessly into such environments, providing essential radiation shielding that helps maintain exposure levels within safe limits while supporting operational workflow.

The system is also designed for straightforward cleaning and maintenance. The smooth, corrosion‑resistant galvanized steel surface allows for easy decontamination, supporting hygiene protocols and helping extend the equipment’s service life with minimal downtime.

Additionally, the JOVI‑50mmpb can be used alongside radiation‑protection lead containers for safe storage and transport of radioactive materials. When integrated into a facility’s radiation safety infrastructure, it enhances overall protection during handling, storage, and transit, supporting compliance with regulatory and industry guidelines.

In summary, the JOVI‑50mmpb Nuclear Radiation Protection System represents a durable, effective shielding solution for gamma and X‑ray radiation, particularly in nuclear medical and industrial applications such as F‑18 hot cells. Its combination of robust materials, ease of maintenance, and compatibility with supplementary safety equipment makes it a practical and reliable choice for organizations committed to advancing radiation safety, reducing exposure risks, and maintaining regulatory compliance.

Applications:

The JOVI Model 1-CF-35 is a state-of-the-art radiation shielding system, designed and manufactured in China to meet rigorous international safety and quality standards. ISO9001-certified, it provides reliable protection in environments where exposure to ionizing radiation must be carefully controlled. With a flexible pricing structure ranging from $20,000 to $50,000 USD and a minimum order quantity of one unit, the system is accessible to organizations of varying scales, from large medical institutions to specialized research facilities.

The system is particularly well-suited for nuclear medical radiation applications, where effective shielding against gamma and X‑ray radiation is essential to protect healthcare professionals, staff, and patients during diagnostic, therapeutic, and radiopharmaceutical handling procedures. An integrated artificial intelligence control system enhances operational precision, enabling real‑time monitoring and automated safety adjustments that improve both workflow efficiency and protection levels.

Another key application is within nuclear radiation hot cells—shielded enclosures used for handling highly radioactive materials. The 1-CF‑35 provides robust attenuation of gamma and X‑ray radiation, reducing operator exposure and supporting compliance with regulatory safety protocols. Additionally, built‑in ultraviolet‑C (UV‑C) and ozone disinfection capabilities help maintain a sterile work environment, minimizing contamination risks in sensitive nuclear and medical settings.

Designed with portability in mind, the system can be flexibly deployed across diverse settings such as nuclear research centers, hospitals, and industrial radiography facilities. Each unit is securely packed in a durable wooden case to ensure safe transport and storage. Delivery is typically completed within 25 working days, with straightforward T/T in advance payment terms to facilitate smooth procurement.

In summary, the JOVI Model 1-CF-35 represents a comprehensive and adaptable radiation shielding solution, combining intelligent control, integrated disinfection, and certified protection. It is an essential tool for institutions engaged in nuclear medical procedures and hot cell operations, helping to advance safety, compliance, and operational reliability in radiation‑sensitive environments.

Customization:

JOVI delivers tailored nuclear radiation protection solutions, designed to align with your operational specifications and safety needs. Our Radiation Protection Lead Cans, represented by the model JOVI-50mmpb (Model: 1-CF-35), are manufactured in China under ISO9001 certification, ensuring consistent quality and dependable performance. Engineered with excellent portability and easy-clean surfaces, these shielding systems are well-suited for deployment in F‑18 hot cell and nuclear medical radiation environments.

We accommodate flexible order volumes starting from one unit, with pricing between $20,000 and $50,000 USD based on configuration. Each system is securely packaged in a reinforced wooden case to ensure damage‑free transit and delivery within 25 working days. Payment is processed via T/T in advance for straightforward order execution.

To support contamination‑controlled operations, our products integrate a dual‑mode disinfection system utilizing ultraviolet‑C light and ozone, helping to maintain a sterile and safe workspace in radiation‑sensitive applications.

Choose JOVI for certified, durable, and adaptable nuclear radiation protection that meets the demands of modern radiological safety and workflow efficiency.

Support and Services:

Our nuclear radiation protection system is backed by a dedicated technical support team focused on ensuring sustained performance, safety, and compliance. We provide end-to-end assistance, including detailed installation guidance, scheduled maintenance, and responsive troubleshooting to keep your operations running smoothly.

To support independent operation, comprehensive user manuals and technical documentation are available, helping you meet safety standards and use the system effectively. We also offer software updates and periodic calibration services to maintain measurement accuracy and system reliability over time.

For facilities with specific operational requirements, we can arrange on‑site training and customized workshops. These sessions are designed to help your team maximize the system’s capabilities and apply industry best practices in radiation safety.

Our commitment is to provide reliable, responsive support that helps you maintain a safe working environment and achieve consistent, accurate radiation monitoring and protection.

Packing and Shipping:

Our nuclear radiation protection system is carefully packaged to ensure it arrives in optimal condition and ready for use. Each unit is secured in a purpose‑designed protective casing that safeguards it from physical impacts and environmental exposure during transit.

High‑quality cushioning materials are integrated within the packaging to absorb shocks and vibrations, minimizing the risk of transport‑related damage. Tamper‑evident seals are applied to confirm that the system remains untouched and intact until it reaches your facility.

We work exclusively with certified logistics providers experienced in handling sensitive and regulated materials. Every shipment is clearly labeled in compliance with applicable safety and transport regulations, including visible handling instructions and product identification for secure transit.

Real‑time tracking details are provided upon dispatch, giving you full visibility over your shipment until delivery. Expedited shipping options are also available to accommodate urgent operational timelines.

Your safety and confidence are our priority—from production through delivery—and we are committed to ensuring every nuclear radiation protection system arrives securely, on time, and in perfect working order.