-

Copper Foil Shielding

-

RF Shielded Doors

-

RF Shielded Windows

-

Radiation Protection Lead Glass

-

Non Magnetic Tool Kit

-

Nuclear Radiation Protection

-

Nuclear Radiation Detector

-

RF Shielded Chamber

-

Honeycomb Waveguide Air Vents

-

Conductive Adhesive Copper Tape

-

Copper Wire Mesh

-

X Ray Lead Glass

-

EMI Shielding Gasket

-

Electrically Conductive Fabric

-

Radiation Protection Door

-

Radiation Protection X Ray

-

Faraday Cage MRI

-

Copper Wire Wool

-

MRI LED Lighting

-

Non Magnetic Wheelchair

-

Non Magnetic Stretcher

-

AnasBrass honeycomb vent Looks Very Nice

AnasBrass honeycomb vent Looks Very Nice -

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

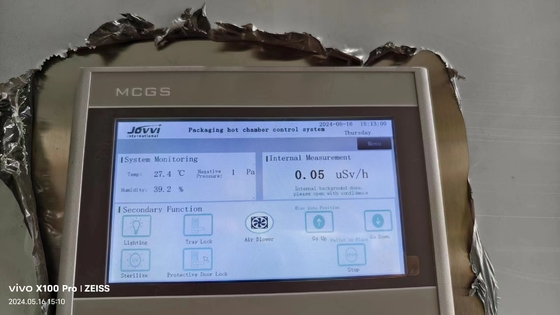

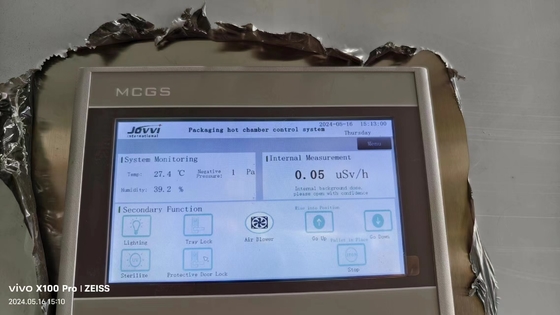

Lu-177 Hot Cell a precision-engineered radiation shielding system for the safe handling, synthesis, dispensing

| Highlight | Lu-177 Hot Cell radiation shielding,precision-engineered nuclear radiation protection,safe handling system for Lu-177 |

||

|---|---|---|---|

Product Detail:

The Lu-177 Hot Cell is a precision-engineered radiation shielding system specifically designed for the safe handling, synthesis, dispensing, and packaging of Lutetium-177 (Lu-177) radiopharmaceuticals in nuclear medicine environments. Built to meet stringent radiological safety and cGMP standards, this hot cell ensures optimal protection for personnel and contamination-free conditions for radiopharmaceutical preparation.

Application:

The Lu-177 Hot Cell delivers safety, precision, and reliability—making it an indispensable system for advanced nuclear medicine facilities engaged in therapeutic isotope applications.

Product Datasheet:

The hot room for repackaging is equipped with an air purification system with negative pressure exhaust ventilation; radiation shielding is used for the repackaging process of radioactive drugs.

The hot cell is composed of three structural components. The control area is located at the top and is equipped with an air purification unit and high-efficiency air filtration units. The control panel is designed for easy daily use and monitoring by operators; The working area is located in the middle, with a lead glass window on the front and two access ports for entering the working area; The auxiliary area is located at the bottom, equipped with a shielding well for the activity meter ionization chamber and a radioactive material transfer device, fully meeting the functional requirements for the use of radioactive drugs during the packaging process.

Integrated stainless steel work area with vertical laminar flow negative pressure ventilation system

Cleanliness level: Class A (ISO 100)

Air supply method: Vertical laminar flow

Laminar flow velocity: 0.35–0.56 m/sec Exhaust airflow rate: 500 m³/h

Sealing method: Inflatable air seal

Supply air filtration: Fully efficient

HEPA 99.995% @ 0.5 µm (H14)

Exhaust air filtration: Radioactive gas filter adsorption

Front shielding: Shielding 30 mm Pb

Side shielding: Shielding 30 mm Pb

Target line shielding: Shielding 30 mm Pb

Internal dimensions: 850 mm (L) × 590 mm (W) × 630 mm (H)

External dimensions: 1175 mm (L) × 1073 mm (W) × 2400 mm (H)

Control: Human-machine interface controls and provides feedback on all information

Visible lead glass window: 320 mm (W) * 220 mm (H)

Dose monitoring display: Integrated into the human-machine interface