-

Copper Foil Shielding

-

RF Shielded Doors

-

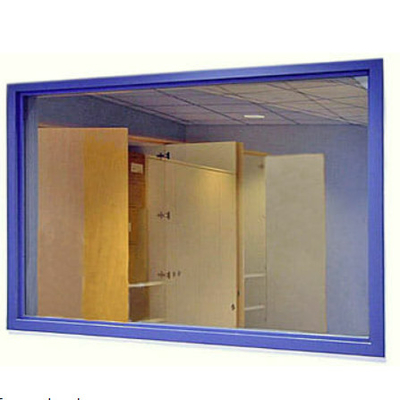

RF Shielded Windows

-

Radiation Protection Lead Glass

-

Non Magnetic Tool Kit

-

Nuclear Radiation Protection

-

Nuclear Radiation Detector

-

RF Shielded Chamber

-

Honeycomb Waveguide Air Vents

-

Conductive Adhesive Copper Tape

-

Copper Wire Mesh

-

X Ray Lead Glass

-

EMI Shielding Gasket

-

Electrically Conductive Fabric

-

Radiation Protection Door

-

Radiation Protection X Ray

-

Faraday Cage MRI

-

Copper Wire Wool

-

MRI LED Lighting

-

Non Magnetic Wheelchair

-

Non Magnetic Stretcher

-

AnasBrass honeycomb vent Looks Very Nice

AnasBrass honeycomb vent Looks Very Nice -

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

SatheeshMRI/RF doors are shining with handles, Thank you My friend.

10mm Lead Glass Radiation Shielding For Ct Room Installation

| Name | Anti Radiation Glasses X-ray Shielding Protective Lead Glass | Usage | Xray CT Room Shielding |

|---|---|---|---|

| Feature | Anti Radiation | Properties | Medical X-ray Equipments & Accessories |

| Pb Contain | 99% | Shape | Sheet Roll |

| Highlight | 10mm lead glass radiation shielding,ct room lead glass radiation shielding,10mm lead glass for x ray room |

||

Lead Product X-Ray Radiation Shielding Lead Glass For CT Room Installation

Lead glass is effective for x-ray shielding and for other forms of radiation shielding due to the attenuation

of ionizing photons as a result of lead’s high atomic number.

The attenuation of radiation increases as the mass density of the attenuating material increases,

and also increases dramatically as the energies of the ionizing photons decrease.

X-rays used in medicine, specifically diagnostic x rays, often have lower energies on the ionizing radiation spectrum,

and are easily shielded by leaded glass. The lead glass used in windows often contains lead that creates an attenuation

equivalent 3mm of pure lead.

Lead Glass is used when a clear view and radiation shielding is of absolute priority in diagnostic, therapy,

isotopic or nuclear radiation sources – used for medical treatment, imaging, testing, inspection, experimentation or energy production.

Typical uses for Lead Glass and X-ray glass include the following:

Medical applications

Viewing windows and insulating glazing for X-Ray rooms

Screens for medical diagnostics – providing protection for doctors and technicians with no reduction in the quality of the observations

Industrial and Nuclear applications

Protection windows in laboratories, radioactive storage stations, nuclear fuel development plants and reprocessing plants

Lenses for safety goggles and protective screens for radiation testing equipment and for electron beam systems and plasma generators.

Airport security X-Ray glass – provides protection from airport luggage inspection equipment.

Please click for lead glass technical data

Please click for additional lead glass application information

Lead Acryllic

Lead acrylic is made from an acrylic co-polymer resin into which lead is chemically introduced as a compound. Lead acrylic contains 30% lead by weight and has a constant density of 1.6 gm/cm.

For the same lead equivalent, acrylic/plastic has to be approximately five times thicker than lead glass – significantly reducing observation capabilities.

Acrylic shields provide shatter-resistant, versatile mobile barriers, modular control booths, window panes, and door glazing.

For a complete listing of products available on this site, go to the products and services index page

| ZF 3 standard | ZF 6 standard | ZF 7 standard | ||||||||||

|

W*L (m/) |

8mm (1.7PB) |

10mm (2.2PB) |

12mm (2.6PB) |

15mm (3.3PB) |

18mm (3.96PB) |

20mm (4.4PB) |

25mm (6.71PB) |

20mm (5.4Pb) |

40mm (10.8Pb) |

20mm (5.8Pb) |

40mm (11.6Pb) |

|

| 0.2*0.3 | 0.2*0.3*8 | 0.2*0.3*10 | 0.2*0.3*12 | 0.2*0.3*15 | 0.2*0.3*18 | 0.2*0.3*20 | 0.2*0.3*25 | 0.2*0.3*20 | 0.2*0.3*40 | 0.2*0.3*20 | 0.2*0.3*40 | |

| 0.3*0.4 | 0.3*0.4*8 | 0.3*0.4*10 | 0.3*0.4*12 | 0.3*0.4*15 | 0.3*0.4*18 | 0.3*0.4*20 | 0.3*0.4*25 | 0.3*0.4*20 | 0.3*0.4*40 | 0.3*0.4*20 | 0.3*0.4*40 | |

| 0.4*0.6 | 0.4*0.6*8 | 0.4*0.6*10 | 0.4*0.6*12 | 0.4*0.6*15 | 0.4*0.6*18 | 0.4*0.6*20 | 0.4*0.6*25 | 0.4*0.6*20 | 0.4*0.6*40 | 0.4*0.6*20 | 0.4*0.6*40 | |

| 0.6*0.8 | 0.6*0.8*8 | 0.6*0.8*10 | 0.6*0.8*12 | 0.6*0.8*15 | 0.6*0.8*18 | 0.6*0.8*20 | 0.6*0.8*25 | 0.6*0.8*20 | 0.6*0.8*40 | 0.6*0.8*20 | 0.6*0.8*40 | |

| 0.6*0.9 | 0.6*0.9*8 | 0.6*0.9*10 | 0.6*0.9*12 | 0.6*0.9*15 | 0.6*0.9*18 | 0.6*0.9*20 | 0.6*0.9*25 | 0.6*0.9*20 | 0.6*0.9*40 | 0.6*0.9*20 | 0.6*0.9*40 | |

| 1*0.8 | 1*0.8*8 | 1*0.8*10 | 1*0.8*12 | 1*0.8*15 | 1*0.8*18 | 1*0.8*20 | 1*0.8*25 | 1*0.8*20 | 1*0.8*40 | 1*0.8*20 | 1*0.8*40 | |

| 1.2*0.8 | 1.2*0.8*8 | 1.2*0.8*10 | 1.2*0.8*12 | 1.2*0.8*15 | 1.2*0.8*18 | 1.2*0.8*20 | 1.2*0.8*25 | 1.2*0.8*20 | 1.2*0.8*40 | 1.2*0.8*20 | 1.2*0.8*40 | |

| 1.2*0.9 | 1.2*0.9*8 | 1.2*0.9*10 | 1.2*0.9*12 | 1.2*0.9*15 | 1.2*0.9*18 | 1.2*0.9*20 | 1.2*0.9*25 | 1.2*0.9*20 | 1.2*0.9*40 | 1.2*0.9*20 | 1.2*0.9*40 | |

| 1.2*1 | 1.2*1*8 | 1.2*1*10 | 1.2*1*12 | 1.2*1*15 | 1.2*1*1.8 | 1.2*1*20 | 1.2*1*25 | 1.2*1*20 | 1.2*1*40 | 1.2*1*20 | 1.2*1*40 | |

| 1.2*1.2 | 1.2*1.2*10 | 1.2*1.2*12 | 1.2*1.2*15 | 1.2*1.2*18 | 1.2*1.2*20 | 1.2*1.2*25 | 1.2*1.2*20 | 1.2*1.2*40 | 1.2*1.2*20 | 1.2*1.2*40 | ||

| 1.5*0.9 | 1.5*0.9*10 | 1.5*0.9*12 | 1.5*0.9*15 | 1.5*0.9*18 | 1.5*0.9*20 | 1.5*0.9*25 | 1.5*0.9*20 | 1.5*0.9*40 | 1.5*0.9*20 | 1.5*0.9*40 | ||

| 1.5*1 | 1.5*1*10 | 1.5*1*12 | 1.5*1*15 | 1.5*1*18 | 1.5*1*20 | 1.5*1*25 | 1.5*1*20 | 1.5*1*40 | 1.5*1*20 | 1.5*1*40 | ||

| 1.5*1.2 | 1.5*1.2*10 | 1.5*1.2*12 | 1.5*1.2*15 | 1.5*1.2*18 | 1.5*1.2*20 | 1.5*1.2*25 | 1.5*1.2*20 | 1.5*1.2*40 | 1.5*1.2*20 | 1.5*1.2*40 | ||

| 1.6*1 | 1.6*1*10 | 1.6*1*12 | 1.6*1*15 | 1.6*1*18 | 1.6*1*20 | 1.6*1*25 | 1.6*1*20 | 1.6*1*40 | 1.6*1*20 | 1.6*1*40 | ||

| 1.6*1.2 | 1.6*1.2*10 | 1.6*1.2*12 | 1.6*1.2*15 | 1.6*1.2*18 | 1.6*1.2*20 | 1.6*1.2*25 | 1.6*1.2*20 | 1.6*1.2*40 | 1.6*1.2*20 | 1.6*1.2*40 | ||

| 1.8*1 | 1.8*1*10 | 1.8*1*12 | 1.8*1*15 | 1.8*1*18 | 1.8*1*20 | 1.8*1*25 | 1.8*1*20 | 1.8*1*40 | 1.8*1*20 | 1.8*1*40 | ||

| 1.8*1.2 | 1.8*1.2*10 | 1.8*1.2*12 | 1.8*1.2*15 | 1.8*1.2*18 | 1.8*1.2*20 | 1.8*1.2*25 | 1.8*1.2*20 | 1.8*1.2*40 | 1.8*1.2*20 | 1.8*1.2*40 | ||

| 2*1 | 2*1*10 | 2*1*12 | 2*1*15 | 2*1*18 | 2*1*20 | 2*1*25 | 2*1*20 | 2*1*40 | 2*1*20 | 2*1*40 | ||

| 2*1.2 | 2*1.2*10 | 2*1.2*12 | 2*1.2*15 | 2*1.2*18 | 2*1.2*20 | 2*1.2*25 | 2*1.2*20 | 2*1.2*40 | 2*1.2*20 | 2*1.2*40 | ||

| 2.4*1.2 | 2.4*1.2*10 | 2.4*1.2*12 | 2.4*1.2*15 | 2.4*1.2*18 | 2.4*1.2*20 | 2.4*1.2*25 | 2.4*1.2*20 | 2.4*1.2*40 | 2.4*1.2*20 | 2.4*1.2*40 | ||

| Standard INTRODUCTION | ZF2 | ZF3 | ZF6 | ZF7 | K509 |

| Structure and component |

Quartz sand 37.03% Lead oxide 59% potassium oxide 3.6% dysprosium oxide 0.18% arsenic oxide 0.19% |

Quartz sand 36.15% Lead oxide 61% potassium oxide 2.5% dysprosium oxide 0.15% arsenic oxide 0.20%

|

Quartz sand 31.03% Lead oxide 65% potassium oxide 2.7% dysprosium oxide 0.26% arsenic oxide 0.45%

|

Quartz sand 28.19% Lead oxide 70% potassium oxide 2.8% dysprosium oxide 0.22% arsenic oxide 0.49%

|

Quartz sand 65% Boric acid 12% Potassium oxide 10% Cerium oxide 1.5% Barium oxide 1.2% other 0.3% |

| Density | 4.2g/cm3 | 4.4g/cm3 | 4.7g/cm3 | 5.2g/cm3 | 2.52g/cm3 |

| Refractive index | 1.6735 | 1.7174 | 1.7552 | 1.8002 | 1.5163 |

| Luminousness | 86% | 86% | 86% | 89% | 86% |

| Lead equivalent unit of optical glass thickness 10mm | 3.2mm Gamma Rays 2.16mmPb X-ray Rays (National standard) | 3.5mm Gamma Rays 2.2mmPb X-ray Rays (National Standard) | 4.1mm Gamma Rays 2.7mmPb X-ray Rays (National Standard) | 4.3mm Gamma Rays 2.9mmPb X-ray Rays (National Standard) | Corrosion resistance |